Fluid Actuation & Control Toulouse

Notre équipe conçoit, fabrique, qualifie et maintien des équipements électro-fluidiques à architectures innovantes adaptés aux spécifications de ses clients.

Nos équipements brevetés peuvent remplacer les servovalves, Direct Drive valves, vannes proportionnelles et permettre un gain de coût, de fiabilité, d’encombrement et de masse. Nos équipements sont aussi particulièrement adaptés à certains environnements sévères : température, vibration notamment.

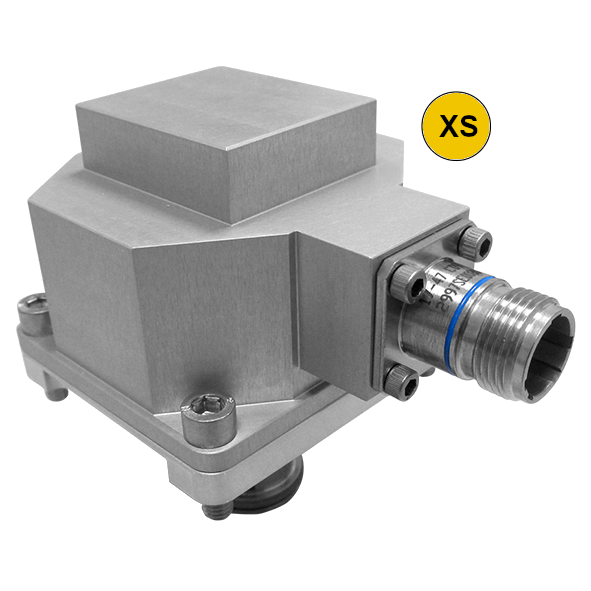

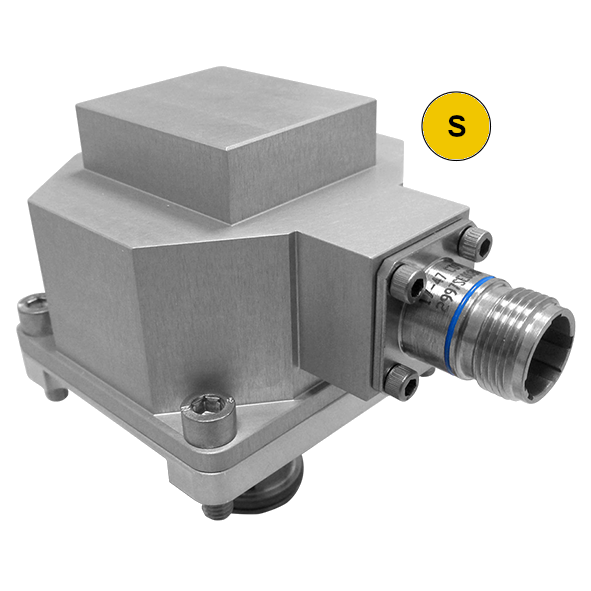

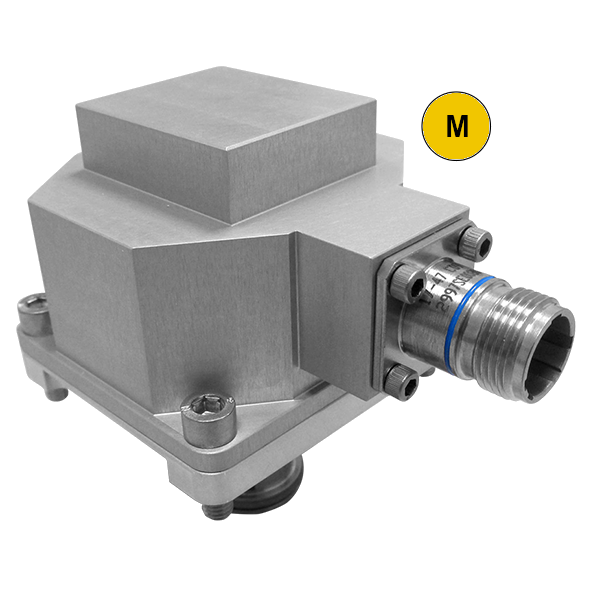

3 moteurs couple

Sans électronique facilement adaptable

XS: très petit • S: petit • M: moyen

3 moteurs couple

Sans électronique facilement adaptable

XS: très petit • S: petit • M: moyen